The Viking 0.045” ER70S-6 Copper-Coated Welding Wire in a 550lb drum is perfect for your welding projects. With unmatched versatility, this wire delivers high-quality welds in GMAW applications.

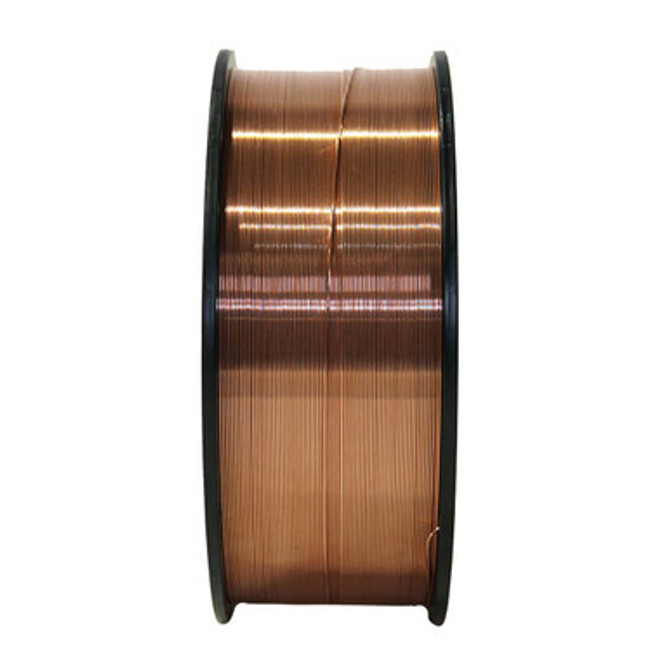

Viking® 0.045” Copper-Coated Welding Wire 550lb Drum

For an impressive welding experience, we offer the Viking 0.045” ER70S-6 Copper-Coated Welding Wire, now available in an impressive 550lb Drum. This colossal offering is more than a spool; it's a testament to the unwavering commitment to excellence that defines us. The copper-coated exterior of the welding wire helps ensure superior electrical conductivity while elevating the welding experience with enhanced arc stability. Crafted for pros who demand precision on an industrial scale, this welding wire's controlled heat transfer capability sets it apart, preventing overheating and ensuring a consistent temperature for flawless welds.

Applications for Viking Welding Wire

Viking copper-coated welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of Viking Welding Wire

The Viking welding wire takes versatility to new heights with its 0.045” diameter, making it the go-to choice for a vast array of applications. This welding wire excels in delivering reliable and robust welds. Housed in a massive 550lb Drum, Viking not only addresses the demands of high-volume welding projects but also showcases its dedication to efficiency and durability. Every weld becomes a symphony of precision, reliability, and a seamless fusion of cutting-edge technology with time-tested craftsmanship.

Shielding Gas Blends for Viking Welding Wire

When it comes to shielding gas blends, Viking can be used with a variety of options, such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

All-position welding is possible with Viking as long as the correct shielding gas blends, welding process, and welding parameters are used.

Viking Welding Wire Industry Standards

Viking copper-coated welding wire meets or exceeds several specifications, including:

- AWS A5.18, ASME SFA-A5.18: ER70S-6

- CWB W48: B-G 49A 3 C1 S6

Viking Welding Wire Storage Instructions

Store the welding wire in a clean and dry environment to prevent moisture absorption, which can lead to rust and overall wire quality degradation. We recommend keeping the wire in its original sealed package until it’s ready for use.

Technical Specs

-

Tier: Viking®

-

Branding: Viking

-

Class: Viking

-

Alloy: S-6

-

Finish: CU

-

Wire Diameter: 0.045

-

Package Type: Drum

-

Package Size: 550

-

Application: MIG

-

Product Length (inches): 21

-

Product Width (inches): 21

-

Product Height (inches): 32

-

Pkgs per Pallet: 2

-

Pallet LBS: 1100

-

AWS: ER70S-6