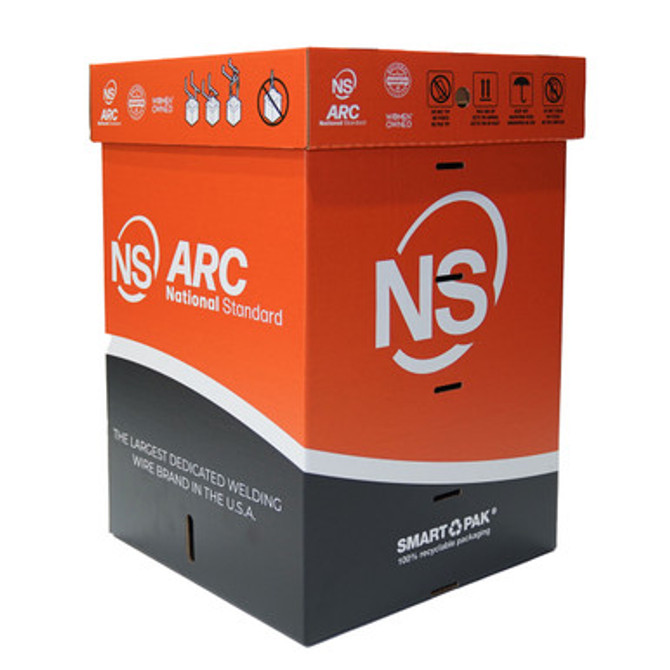

The reliable and strong Tru-Core® 0.045” MC70C Metal-Cored Welding Wire in a 500lb Drum is a gas-shielded electrode that works excellently with numerous different types of welding applications, such as general fabrication and pipe welding.

Tru-Core® 0.045” MC70C Metal-Cored Welding Wire 500lb Drum

The Tru-Core® 0.045” MC70C Metal-Cored Welding Wire in a 500lb Drum is a reliable and strong gas-shielded electrode that can produce high-quality welds when used with shielding gas blends of 75-95% argon and balance carbon dioxide. Its higher deposition rates contribute to an increase in productivity, streamlining your welding operations into more efficient processes without sacrificing quality.

100% Made in the U.S.A. with American steel to meet “Buy America” Standards.

Applications for Tru-Core® Welding Wire

Tru-Core® metal-cored welding wire is best suited for the following applications:

- Agricultural Equipment

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Structural Steel

- Trailers

Advantages of Tru-Core® Welding Wire

Our Tru-Core® 0.045” MC70C welding wire offers superior feedability, becoming a cost-effective solution for a wide range of welding applications, especially those that demand a minimum tensile strength of 70,000 psi. Our high-quality welding wire produces a lower heat input than other types, which can effectively reduce distortion during the welding process. This helps preserve the quality of the weld.

Shielding Gas Blends for Tru-Core® Metal-Cored Welding Wire

Typical application shielding gas blends for our Tru-Core® metal-cored welding wire include:

- 75-95% Argon/Balance CO2

- Flow rate: 35-45 CFH

All-position welding is possible when using the correct shielding gas blends, welding process, and welding parameters.

Metal-Cored Welding Wire Industry Standards

Tru-Core® meets or exceeds several specifications, including:

- AWS A5.18/A5.18M, ASME SFA-A5.18 E70C-3M H4, E70C-6M H4

- AWS A5.36 E70T15-M12P2-CS1 H4, E70T15-M20P2-CS1 H4, E70T15-M21P2-CS1 H4

- CWB W48: E490T15-M12A3-CS1-H4

Metal-Cored Welding Wire Storage Instructions

Tru-Core® metal-cored welding wire should be stored in a dry, enclosed environment and in its originally sealed package.

Technical Specs

-

Tier: National-Arc

-

Branding: Tru-Core

-

Class: Cored

-

Alloy: MC70C

-

Finish: MC

-

Wire Diameter: 0.045

-

Package Type: Drum

-

Package Size: 500

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 31.25

-

Pkgs per Pallet: 4

-

Pallet LBS: 2000

-

AWS: E70C-6M, E70C-3M H4