Now our welders have the strength to achieve efficient welding on large projects with Tru-Core® 0.062” FC71T-12C Flux-Cored Welding Wire in a 33lb spool, offering superior penetration on thicker materials.

Tru-Core® 0.062” FC71T-12C Flux-Cored Welding Wire 33lb Spool

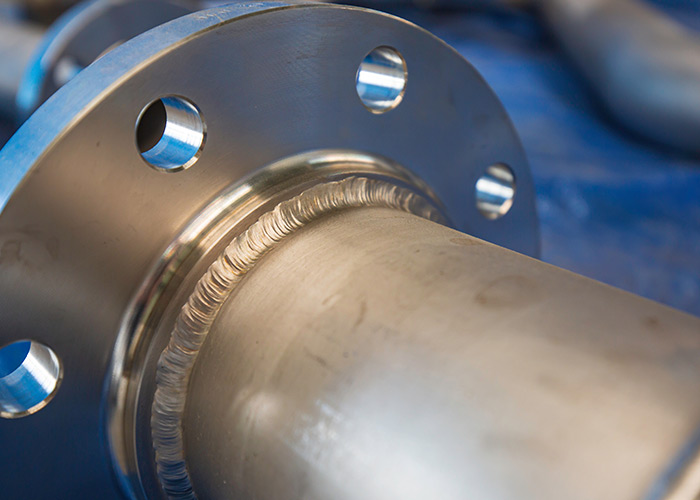

The Tru-Core® 0.062” FC71T-12C Flux-Cored Welding Wire in a 33lb spool is the best choice for those who weld with E71T-1C, E71T-9C, and E71T-12C H8 wires. This high-quality welding wire is engineered by our experts to exceed beyond industry specifications and welder expectations. Offering deeper penetration, especially on thicker metals, our welding wire features a smooth stable arc transfer that promotes much more control over the welding process.

100% Made in the U.S.A. with American steel to meet “Buy America” Standards.

Applications for Tru-Core® Welding Wire

Tru-Core® flux-cored welding wire is best suited for the following applications:

- Agricultural Equipment

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Structural Steel

- Trailers

Advantages of Tru-Core® Welding Wire

With its small-droplet arc transfer, minimal spatter, and fast-freezing slag, our Tru-Core® 0.062” FC71T-12C welding wire ensures excellent bead appearance and promotes uniform, flat bead shapes in all positions. Whether the project demands welding in-position or out-of-position in multi-pass and single-pass operations, this is the wire of choice. Its outstanding feedability and beneficial mechanical properties gives our welders the power to achieve high-quality welds with ease.

Shielding Gas Blends for Tru-Core® Flux-Cored Welding Wire

For shielding gas blends, Tru-Core® FC 71T-12C can be used with a variety of options, such as:

- 100% CO2

- Flow rate: 35-45 CFH

Whether you’re welding in vertical, horizontal, or overhead positions, the right combination of shielding gas blends, welding process, and welding parameters enables you to achieve exceptional welds with ease.

Flux-Cored Welding Wire Industry Standards

Tru-Core® meets or exceeds several specifications, including:

- AWS A5.20: E71T-1C H8, E71T-1C H8, E71T-9C H8, E71T-12C H8

- ASME SFA-A5.20: E71T-1C H8, E71T-9C H8, E71T-12C H8

Flux-Cored Welding Wire Storage Instructions

In order to properly enjoy the full welding power of NS ARC's Tru-Core® FC 71T-12C, we recommend that you store the wire in a dry, enclosed environment in its originally sealed package. This can help prolong the service life of the welding wire and keep your welds at optimal strength.

Technical Specs

-

Tier: National-Arc

-

Branding: Tru-Core

-

Class: Cored

-

Alloy: FC71T-12C

-

Finish: FC

-

Wire Diameter: 0.062 (1/16)

-

Package Type: Spool

-

Package Size: 33

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2376

-

AWS: E71T-1C, E71T-9C, E71T-12C H8