The Satin Glide™ 409Cb 0.030” Stainless-Steel Welding Wire in a 30lb spool produces solid and reliable welds that can withstand some of the more corrosive environments. It offers greater weldability to allow for an easy and efficient welding experiences.

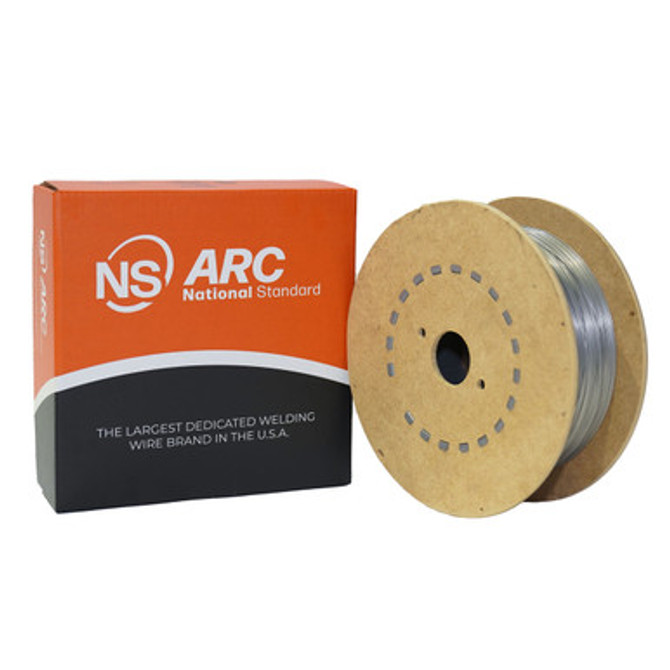

Satin Glide™ 409Cb 0.030” Stainless-Steel Welding Wire 30lb Spool

The Satin Glide™ 409Cb 0.030” Stainless-Steel Welding Wire in a 30lb spool is incredibly effective for joining and welding 409-type and other dissimilar base metal welding so welders can join different types of metals together. A versatile and strong ferritic filler metal, this wire brings its benefits to a wide variety of applications within numerous industries, including automotive, transportation, and shipbuilding.

Applications for Satin Glide™ Welding Wire

Satin Glide™ welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the Satin Glide™ Welding Wire

The Satin Glide™ 409Cb welding wire features high-temperature resistance so that it can be used in elevated temperature environments. Promoting excellent flow characteristics, this type of welding wire produces smooth and clean welds with pleasing bead appearances while offering good penetration.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER409Nb

- ASME SFA-A5.9: ER409Nb

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

If possible, the best way to store the welding wire is off the ground to avoid contact with moisture and potential contaminants. You should also avoid storing it in areas prone to high humidity or moisture to prevent rust and degradation.

Technical Specs

-

Tier: National-Arc

-

Branding: Satin Glide

-

Class: Stainless

-

Alloy: 409CB

-

Finish: STN

-

Wire Diameter: 0.030

-

Package Type: Spool

-

Package Size: 30

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2160

-

AWS: ER409CB, ER409Nb