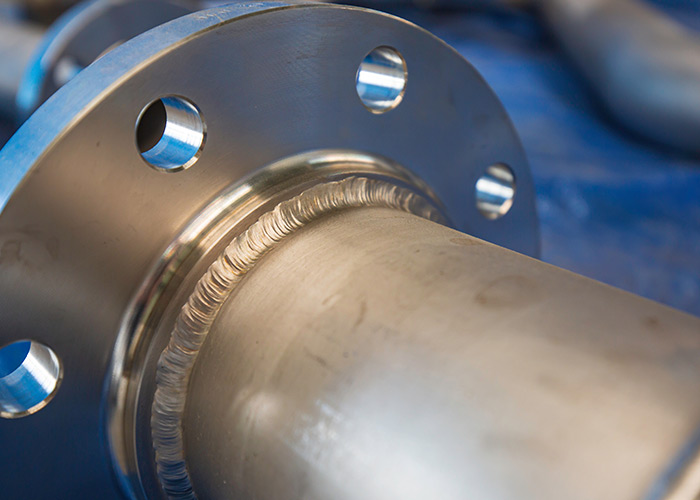

We are offering the Satin Glide® 316LHS 0.045” Stainless-Steel Welding Wire in a robust 500lb Drum. This high-quality filler metal is engineered for superior corrosion resistance, making it a top-tier choice for welding in harsh and corrosive environments.

Satin Glide™ 316LHS 0.045” Stainless-Steel Welding Wire 500lb Drum

The Satin Glide™ 316LHS 0.045” Stainless-Steel Welding Wire in a 500lb drum is a reliable filler metal that can be used to achieve tougher welds. This wire is manufactured by our experts with an emphasis on weld strength, allowing our welders to achieve high-quality welds that can withstand heavy loads and stresses. Stainless steel’s inherent corrosion resistance enhances this wire’s resistance to corrosion.

Applications for Satin Glide™ Welding Wire

Satin Glide™ welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the Satin Glide™ Welding Wire

The Satin Glide™ 316LHS welding wire is composed of 0.03% maximum carbon, 18-20% chromium, 12-14% nickel, 0.7-1% silicon, and 2-2.5% molybdenum. The higher silicon improves the wash and wetting of the welded material for smoother welding. The added molybdenum provides enhanced resistance to a wide range of chemicals.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER316Si, ER316LSi

- ASME SFA-A5.9: ER316Si, ER316LSi

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

At NS ARC, we recommend that you store the welding wire in a dry, enclosed environment in order to prevent the wire from losing its quality or performance. The original sealed package is the ideal choice for this.

Technical Specs

-

Tier: National-Arc

-

Branding: Satin Glide

-

Class: Stainless

-

Alloy: 316LHS

-

Finish: STN

-

Wire Diameter: 0.045

-

Package Type: Drum

-

Package Size: 500

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 31.25

-

Pkgs per Pallet: 4

-

Pallet LBS: 2000

-

AWS: ER316LSi