The Satin Glide™ 316LHS 0.035” Stainless-Steel Welding Wire in a 30lb spool features higher silicon content for better wetting characteristics. Its lower carbon content also helps reduce the risk of carbide precipitation for producing stronger welds.

Satin Glide™ 316LHS 0.035” Stainless-Steel Welding Wire 30lb Spool

The Satin Glide™ 316LHS 0.035” Stainless-Steel Welding Wire in a 30lb spool delivers exceptional performance, making it the best choice for welders who handle diverse applications. With its natural resistance to corrosion, this type of wire is more than capable of handling difficult jobs in corrosive environments. It also promotes smooth arc characteristics along with consistent feeding and deposition rates for greater efficiency.

Applications for Satin Glide™ Welding Wire

Satin Glide™ welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

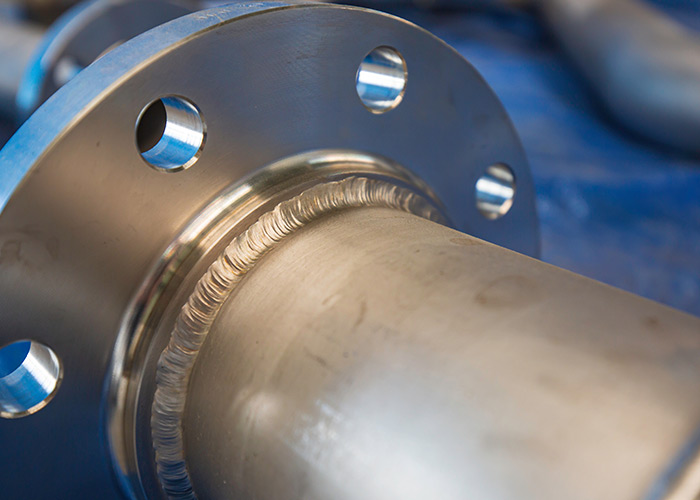

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the Satin Glide™ Welding Wire

The Satin Glide™ 316LHS welding wire is the best choice for dealing with the tougher jobs. Its composition includes less carbon to reduce the risk of carbide precipitation, protecting the weld from sensitization. The composition also includes higher levels of silicon content, which improve the wetting of the weld material. This can potentially lead to a quicker and more efficient welding job.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER316Si, ER316LSi

- ASME SFA-A5.9: ER316Si, ER316LSi

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

At NS ARC, we recommend that you store the welding wire in a dry, enclosed environment in order to prevent the wire from losing its quality or performance. The original sealed package is the ideal choice for this.

Technical Specs

-

Tier: National-Arc

-

Branding: Satin Glide

-

Class: Stainless

-

Alloy: 316LHS

-

Finish: STN

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 30

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2160

-

AWS: ER316LSi