The high-quality Satin Glide™ 309L 0.035” Stainless-Steel Welding Wire 30lb spool exhibits some noticeable benefits for the next welding job, including improved wash and wetting behavior and stabilized and controlled arc stability.

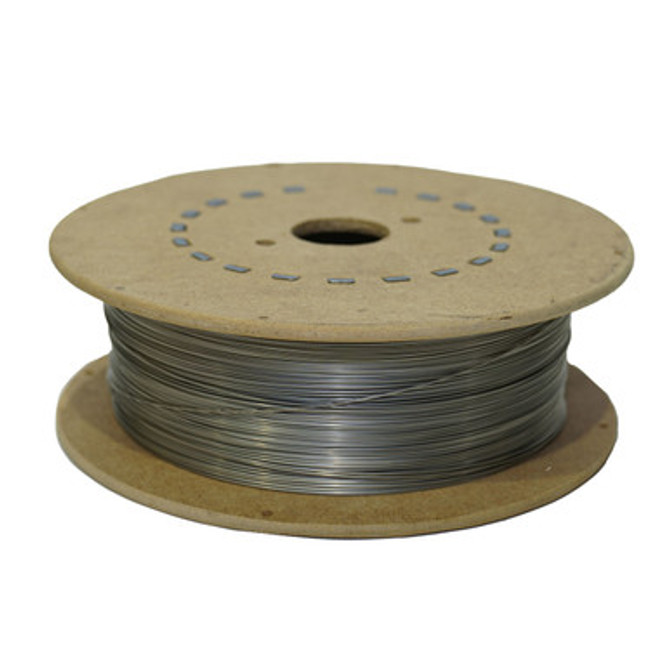

Satin Glide™ 309L 0.035” Stainless-Steel Welding Wire 30lb Spool

The Satin Glide™ 309L 0.035” Stainless-Steel Welding Wire in a 30lb spool is the right choice for welders who need the assured corrosion resistance that this type of filler metal offers. Featuring a lower carbon content, this type of welding wire is best suited for applications where reduced carbon precipitation is desired to prevent sensitization and intergranular corrosion. This helps protect the welds from harsh conditions and works to maintain their integrity and longevity when faced with demanding environments.

Applications for Satin Glide™ Welding Wire

Satin Glide™ welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the Satin Glide™ Welding Wire

The Satin Glide™ welding wire offers stable and controlled arc ignition for greater precision and control over the welding process. This filler metal is excellent for joining mild steel or low alloy steel to stainless steels, for joining dissimilar stainless steels such as 409 to itself or to 304L stainless, as well as for joining 309 base metal. This brings both flexibility and adaptability directly to the job.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER309, ER309L

- ASME SFA-A5.9: ER309, ER309L

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

You can preserve the quality and performance of your welding wire by keeping it in a dry environment to prevent moisture from contaminating it. Avoid storing the wire in areas prone to high humidity and moisture.

Technical Specs

-

Tier: National-Arc

-

Branding: Satin Glide

-

Class: Stainless

-

Alloy: 309L

-

Finish: STN

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 30

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2160

-

AWS: ER309L