Satin Glide® 308L Stainless-Steel Welding Wire is a reliable filler metal that is often utilized in welding applications specifically for joining or repairing stainless-steel components made from the 304 or 304L stainless-steel alloys. It provides excellent corrosion resistance, high strength, and good weldability and produces clean and smooth welds with minimal spatter and distortion.

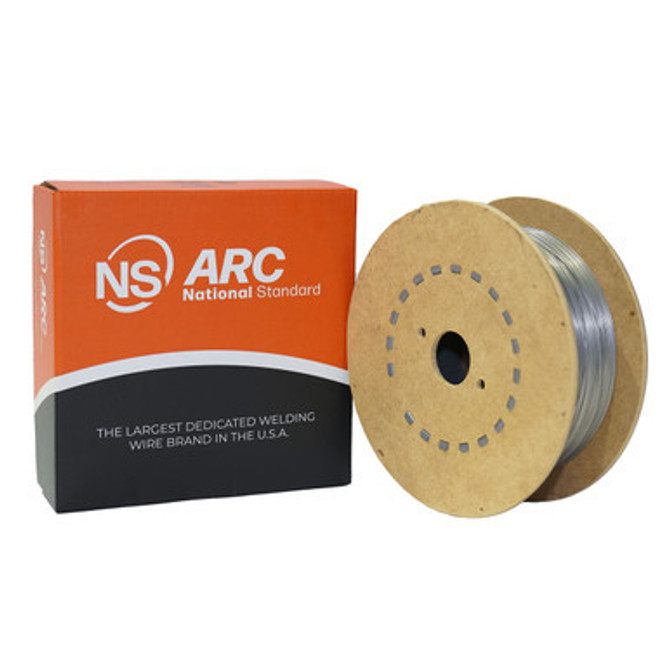

Satin Glide® 308L Stainless-Steel Welding Wire

NS ARC’s Satin Glide® 308L Stainless-Steel Welding Wire is a high-quality filler metal for joining or repairing stainless-steel components made from 304L stainless-steel alloy. Manufactured to meet and exceed quality standards, this reliable welding wire is designed to offer excellent corrosion resistance, even in harsh environments. The low carbon content minimizes the formation of chromium carbides, which can lead to sensitization and corrosion issues. It also offers good weldability, ensuring sound welds with minimal risk of cracking or distortion. The wire produces smooth and clean weld beads with minimal spatter and good wetting characteristics.

This type of welding wire features lower carbon content, which helps prevent issues that can occur in high-temperature environments, making it suitable for welding applications where maintaining the mechanical properties of the base metal is critical.

The Satin Glide® 308L stainless-steel welding wire offers exceptional flexibility and support for your GMAW operations. With its enhanced feedability and ability to provide precise wire positioning, you can easily achieve accurate and consistent welds. Our unique wire cleaning process means that surface residuals are effectively eliminated, ensuring clean and pristine welds. Additionally, tight ferrite controls contribute to superior resistance to corrosion, making this welding wire a valuable choice for applications demanding optimal performance in corrosive environments.

Experience the benefits of Satin Glide® 308L stainless-steel welding wire’s unique surface finish and trust in the quality and performance of Satin Glide® to deliver remarkable results. Contact us today to learn more about our stainless-steel welding wire solutions and how they can enhance your welding capabilities.

Applications for Satin Glide® 308L Welding Wire

Satin Glide® 308L stainless-steel welding wire is best suited for the following applications:

- Agricultural Equipment

- Automotive Manufacturing

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Other Industrial Applications for Satin Glide® 308L Welding Wire

This type of welding wire is commonly used in industries such as food processing, chemical processing, pharmaceutical manufacturing, and dairy equipment, where corrosion resistance and hygiene are of utmost importance. The Satin Glide® 308L stainless-steel welding wire can be used for all metal transfer modes of GMAW, robotic, mechanized, or semi-automatic welding. Excelling in single and multi-pass weldments, this wire brings versatility and adaptability right to your welding projects. Satin Glide® is particularly effective for dissimilar base metal welding, enabling you to join different materials with ease.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER308, ER308L

- ASME SFA-A5.9: ER308, ER308L

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

For storing the welding wire, make sure that it is kept in a dry location in a clean and organized manner to prevent any contact with dirt, dust, or debris, which can affect the wire’s overall quality and performance.

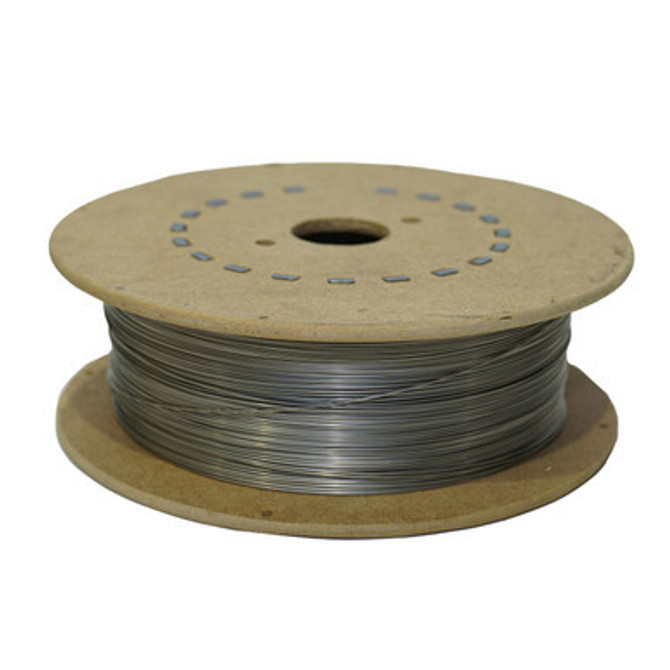

Technical Specs

-

Tier: National-Arc™

-

Branding: Satin Glide®

-

Class: Stainless

-

Alloy: 308L

-

Finish: STN

-

Wire Diameter: 0.035

-

Package Type: Wood Reel

-

Package Size: 600

-

Application: MIG

-

Product Length (inches): 30

-

Product Width (inches): 30

-

Product Height (inches): 17

-

Pkgs per Pallet: 2

-

Pallet LBS: 1200

-

AWS: ER308L