The NS National-Arc™ Copper-Glide™ NS 115US 0.045” Copper-Coated Welding Wire in a 500lb Drum is a cost-effective solution for welders, offering unparalleled performance without breaking the bank.

NS National-Arc™ Copper-Glide™ NS 115US 0.045” Copper-Coated Welding Wire 500lb Drum

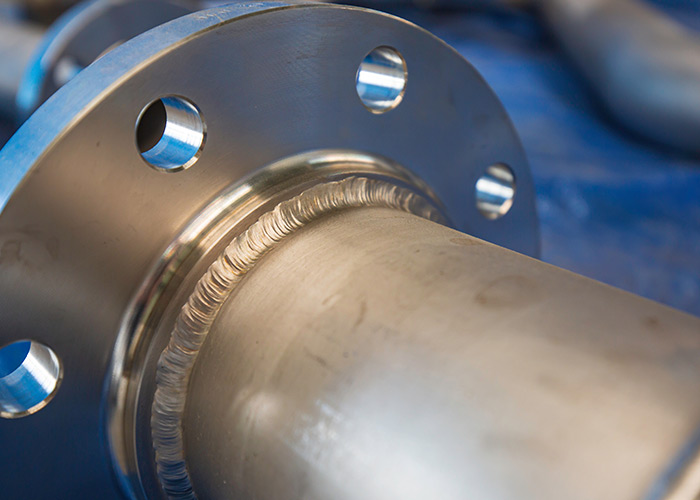

The NS National-Arc™ Copper-Glide™ NS 115US 0.045” Copper-Coated Welding Wire in a 500lb Drum provides a stronger and more satisfying welding experience, creating exceptional results for users of ER70S-6 wire. Engineered with an emphasis on weld strength, this wire features a copper coating that enhances the wire's corrosion resistance, contributing to the longevity of the welds and the overall structural integrity of the project.

100% Made in the U.S.A. with American steel to meet “Buy America” Standards.

Applications for NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 115US welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

The NS National-Arc™ Copper-Glide™ NS 115US welding wire delivers incredible smoothness during the welding process, allowing our welders to achieve consistent and clean welds. Consistent and uniform hardness across the weld ensures stability and reliability in the welded joint. This is critical in applications where even distribution of mechanical properties is essential for the overall structural integrity of the project.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

For optimal performance, Copper-Glide™ NS 115US requires specific shielding gas blends such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

It is also compatible with all-position welding, provided that the correct shielding gas blends, welding process, and welding parameters are used.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 115US meets or exceeds various industry standards such as:

- AWS A5.18: ER70S-6 H4, AWS A5.18M: ER48S-6

- ASME SFA-5.18: ER70S-6

- AWS A5.17: EH11K

- MIL-E-273765/1: MIL-70S-6

- CWB W48: B-G 49A 3 C1 S6

- ABS

Copper-Coated Welding Wire Storage Instructions

For maximum quality and performance protection, you can easily store the welding wire in a dry and enclosed environment to prevent moisture buildup. You can also keep the wire in its original sealed package.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 115US

-

Finish: CU

-

Wire Diameter: 0.045

-

Package Type: Drum

-

Package Size: 500

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 31.25

-

Pkgs per Pallet: 4

-

Pallet LBS: 2000

-

AWS: ER70S-6