Reduce oxidation worries with NS National-Arc™ Copper-Glide™ NS 115US 0.035” Copper-Coated Welding Wire in a 33lb Spool, providing a protective coating that minimizes oxidation and enhances the overall quality of your welds.

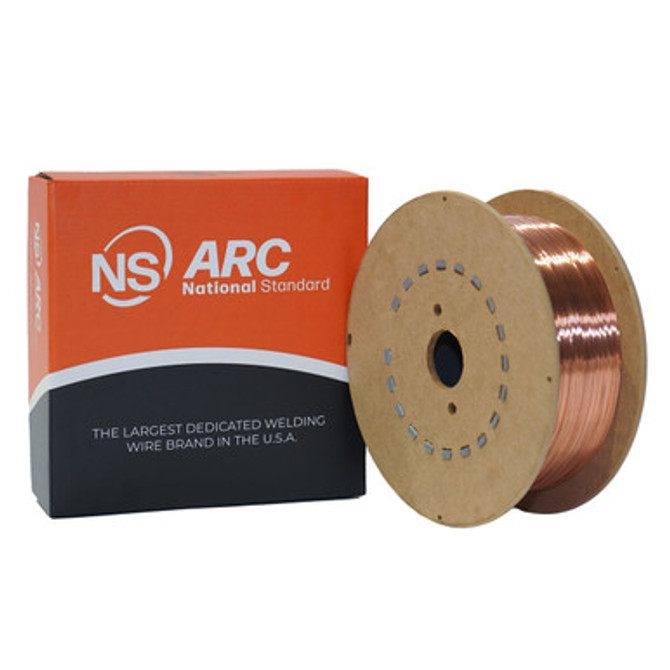

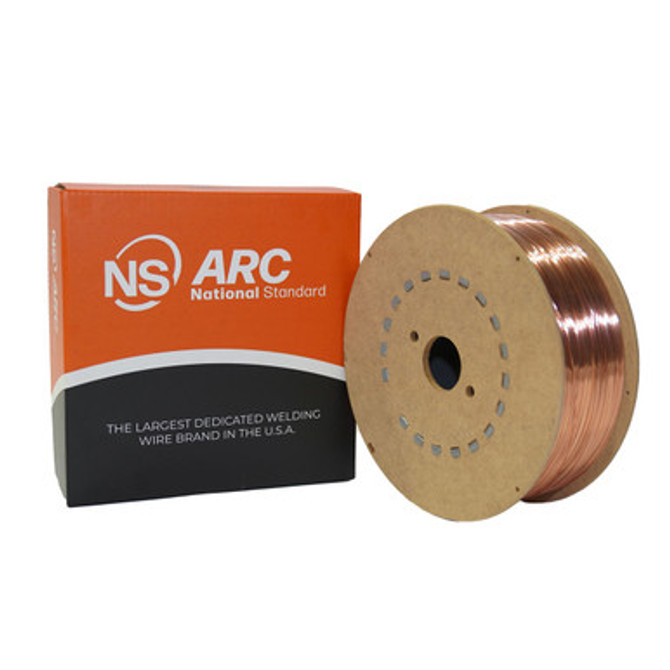

NS National-Arc™ Copper-Glide™ NS 115US 0.035” Copper-Coated Welding Wire 33lb Spool

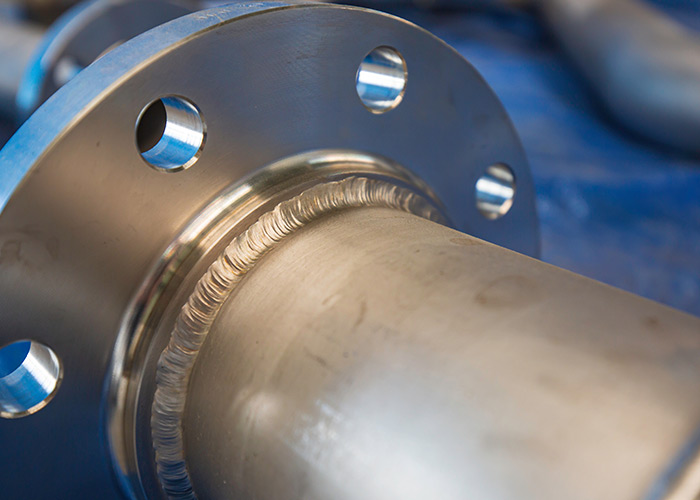

The NS National-Arc™ Copper-Glide™ NS 115US 0.035” Copper-Coated Welding Wire in a 33lb Spool is a premium mild steel solid filler metal. It delivers superior results for every weld and ensures a smooth and uniform welding arc, minimizing spatter and achieving excellent bead appearance for ER70S-6 applications.

100% Made in the U.S.A. with American steel to meet “Buy America” Standards.

Applications for NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 115US welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

The NS National-Arc™ Copper-Glide™ NS 115US welding wire exhibits excellent feedability, precise wire positioning, and higher silicon content for flatter bead profiles. This welding wire is meticulously crafted by our team of experts in our Stillwater, Oklahoma, plant, an ISO 9001:2015 facility, to exceed your expectations in MIG operations.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 115US Welding Wire

For optimal performance, Copper-Glide™ NS 115US requires specific shielding gas blends such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

It is also compatible with all-position welding, provided that the correct shielding gas blends, welding process, and welding parameters are used.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 115US meets or exceeds various industry standards such as:

- AWS A5.18: ER70S-6 H4, AWS A5.18M: ER48S-6

- ASME SFA-5.18: ER70S-6

- AWS A5.17: EH11K

- MIL-E-273765/1: MIL-70S-6

- CWB W48: B-G 49A 3 C1 S6

- ABS

Copper-Coated Welding Wire Storage Instructions

For maximum quality and performance protection, you can easily store the welding wire in a dry and enclosed environment to prevent moisture buildup. You can also keep the wire in its original sealed package.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 115US

-

Finish: CU

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 33

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2376

-

AWS: ER70S-6