The improved aesthetics of welded joints achieved with NS National-Arc™ Copper-Glide™ NS 115 0.035” Copper-Coated Welding Wire in a 45lb Spool make it a preferred choice for those seeking top-notch appearance in ER70S-6 applications.

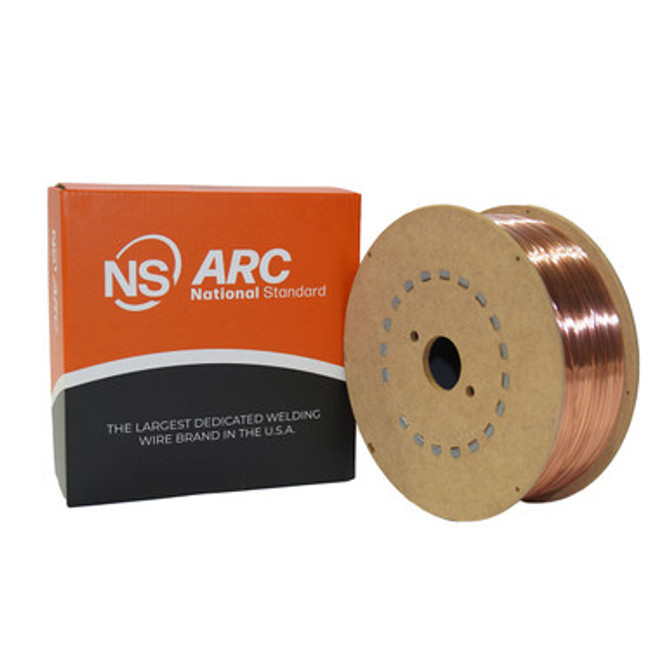

NS National-Arc™ Copper-Glide™ NS 115 0.035” Copper-Coated Welding Wire 45lb Spool

The NS National-Arc™ Copper-Glide™ NS 115 0.035” Copper-Coated Welding Wire in a 45lb Spool combines the mechanical properties of a steel core with the beneficial characteristics provided by the copper coating. This type of welding wire is widely used in industrial and construction settings where reliable and high-quality welds are essential.

Applications for NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 115 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 115 welding wire features a smooth and consistent copper coating, which facilitates the efficient feeding of the wire through the welding torch. This results in improved feedability, reducing the risk of feeding-related issues such as jams or interruptions during welding.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

To achieve optimal results, consider using the following shielding gas blends with NS National-Arc™ Copper-Glide™ NS 115 copper-coated welding wire:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

With the correct selection of shielding gas blends, welding process, and welding parameters, NS National-Arc™ Copper-Glide™ NS 115 allows for all-position welding, providing you with the versatility and freedom to tackle any welding task with confidence.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 115 meets or exceeds various industry standards such as:

- AWS A5.18: ER70S-6 H4

- ASME SFA-A5.18: ER70S-6

- AWS A5.17: EH11K

- CWB W48: B-G 49A 3 C1 S6

- ABS Certified Product - Learn More

Copper-Coated Welding Wire Storage Instructions

To preserve the quality and performance of Copper-Glide™ NS 115, it is essential to store the welding wire in a dry and enclosed environment, preferably within its original sealed package. By following proper storage practices, you can extend the shelf life and ensure consistent welding results.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 115

-

Finish: CU

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 45

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 3240

-

AWS: ER70S-6