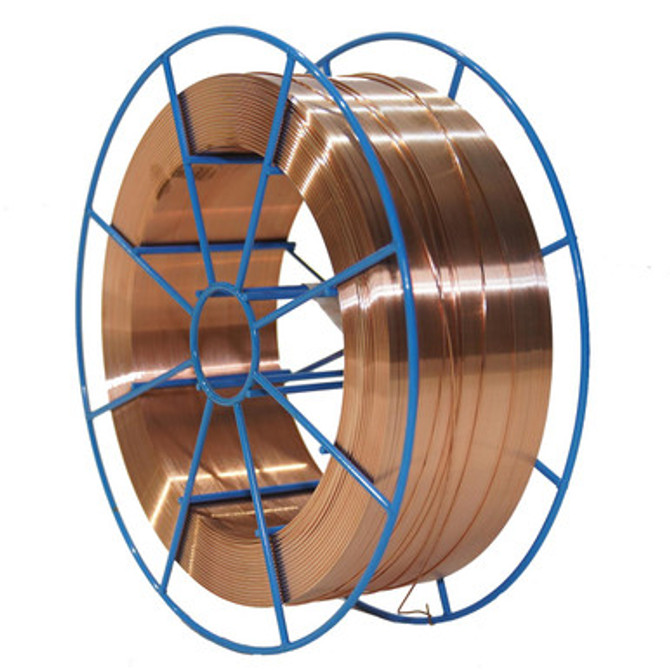

Our NS National-Arc™ Copper-Glide™ NS 115 0.030” Copper-Coated Welding Wire in a 250lb Drum can help our welders achieve better arc characteristics, as this premium copper-coated mild steel solid filler metal provides a smooth and uniform welding arc.

NS National-Arc™ Copper-Glide™ NS 115 0.030” Copper-Coated Welding Wire 250lb Drum

The NS National-Arc™ Copper-Glide™ NS 115 0.030” Copper-Coated Welding Wire in a 250lb Drum allows our welders to experience reliable and consistent welding performance. The wire composition, which includes increased levels of manganese and silicon, ensures excellent conductivity and arc stability, resulting in welds that meet or exceed industry standards.

Applications for NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 115 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 115 welding wire is engineered by our experts in our in our Stillwater, Oklahoma, plant, an ISO 9001:2015 facility, guaranteeing the fact that this wire is crafted with special attention to deliver exceptional performance. This wire is designed with an emphasis on high tensile strength, ensuring that the resulting welds exhibit robust mechanical integrity. This attribute is crucial for applications that demand durability and resistance to applied forces, making it suitable for structural and load-bearing projects.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 115 Welding Wire

To achieve optimal results, consider using the following shielding gas blends with NS National-Arc™ Copper-Glide™ NS 115 copper-coated welding wire:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

With the correct selection of shielding gas blends, welding process, and welding parameters, NS National-Arc™ Copper-Glide™ NS 115 allows for all-position welding, providing you with the versatility and freedom to tackle any welding task with confidence.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 115 meets or exceeds various industry standards such as:

- AWS A5.18: ER70S-6 H4

- ASME SFA-A5.18: ER70S-6

- AWS A5.17: EH11K

- CWB W48: B-G 49A 3 C1 S6

- ABS Certified Product - Learn More

Copper-Coated Welding Wire Storage Instructions

To preserve the quality and performance of Copper-Glide™ NS 115, it is essential to store the welding wire in a dry and enclosed environment, preferably within its original sealed package. By following proper storage practices, you can extend the shelf life and ensure consistent welding results.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 115

-

Finish: CU

-

Wire Diameter: 0.030

-

Package Type: Drum

-

Package Size: 250

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 16

-

Pkgs per Pallet: 4

-

Pallet LBS: 1000

-

AWS: ER70S-6