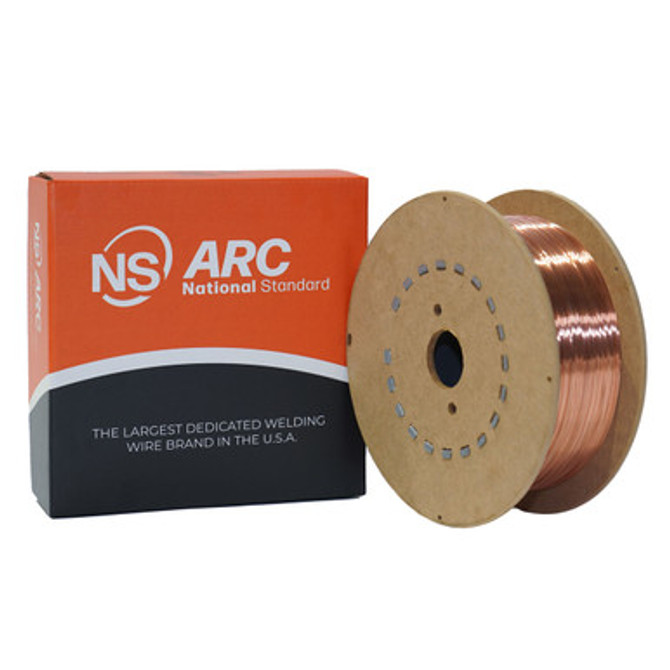

The reliable and strong NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire in a 45lb Spool significantly reduces spatter and copper flaking, minimizing post-weld cleaning efforts.

NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire 45lb Spool

The NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire in a 45lb Spool features a unique composition. The 0.5% molybdenum, which ensures the retention of hardness within the weld even after post-weld heat treatment. Additionally, the inclusion of manganese and silicon further enhances its capabilities by promoting the formation of a smooth and uniform weld bead while effectively reducing spatter.

Applications for NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 102 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 102 welding wire emphasizes excellent characteristics that support the strength of the weld. Its copper coating improves its smooth feedability for a much more productive welding operation while reducing spatter and copper flaking.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

To achieve optimal results, consider using the following shielding gas blends with NS National-Arc™ Copper-Glide™ NS 102:

- 100% CO2: Ideal for ER80S-D2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2: Suitable for ER90S-D2

- Flow rate of 35-50 CFH

When paired with the correct shielding gas blends, welding process, and welding parameters, our Copper-Glide™ NS 102 enables welding in all positions, offering versatility and convenience for various welding projects.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 102 meets or exceeds various industry standards such as:

- AWS A5.28: ER80S-D2 (100% CO2), ER90S-D2 (Mixed)

- ASME SFA-A5.28: ER80S-D2

- CWB W48: B-G 55A 3 C1 S4 M31

- AWS A5.23/A5.23M: EA3K

Copper-Coated Welding Wire Storage Instructions

To ensure the longevity and quality of the welding wire, it should be stored in a dry, enclosed environment. Proper care and maintenance will help keep your wire in the best condition for welding.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 102

-

Finish: CU

-

Wire Diameter: 0.045

-

Package Type: Spool

-

Package Size: 45

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 3240

-

AWS: ER80S-D2, ER90S-D2