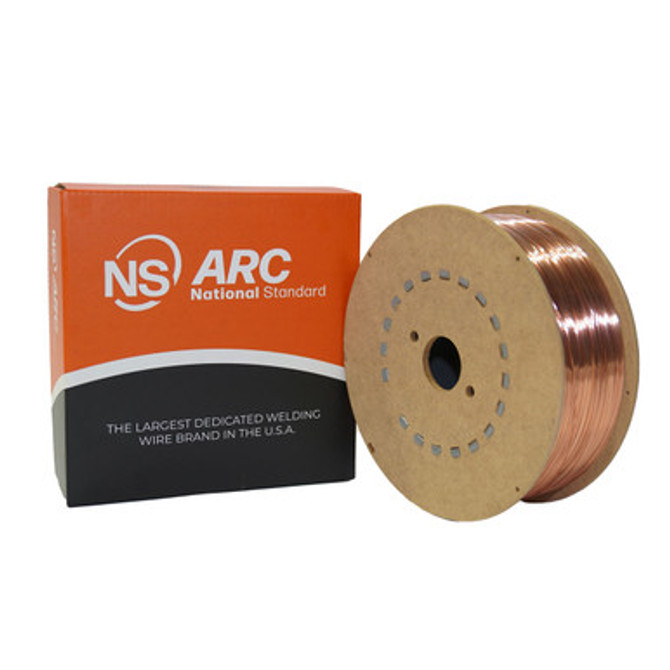

The NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire in a 500lb Drum is a premium copper-coated low alloy filler metal designed for exceptional performance in heavy-duty ER80S-D2 and ER90S-D2 applications.

NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire 500lb Drum

The NS National-Arc™ Copper-Glide™ NS 102 0.045” Copper-Coated Welding Wire in a 500lb Drum is designed to promote quality and strength. It features excellent heat conductivity, which contributes to consistent heat distribution during welding. This proper heat management is necessary for preventing distortion and other welding issues.

Applications for NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 102 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 102 welding wire can be used with robotic, mechanized, or semi-automatic welding and with all metal transfer modes of GMAW. This type of welding wire is also suited for ASTM A182, A217, A234, and A335 high-temperature pipe, fittings, flanges, and valves as well as for A336 pressure vessel forgings.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 102 Welding Wire

To achieve optimal results, consider using the following shielding gas blends with NS National-Arc™ Copper-Glide™ NS 102:

- 100% CO2: Ideal for ER80S-D2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2: Suitable for ER90S-D2

- Flow rate of 35-50 CFH

When paired with the correct shielding gas blends, welding process, and welding parameters, our Copper-Glide™ NS 102 enables welding in all positions, offering versatility and convenience for various welding projects.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 102 meets or exceeds various industry standards such as:

- AWS A5.28: ER80S-D2 (100% CO2), ER90S-D2 (Mixed)

- ASME SFA-A5.28: ER80S-D2

- CWB W48: B-G 55A 3 C1 S4 M31

- AWS A5.23/A5.23M: EA3K

Copper-Coated Welding Wire Storage Instructions

To ensure the longevity and quality of the welding wire, it should be stored in a dry, enclosed environment. Proper care and maintenance will help keep your wire in the best condition for welding.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 102

-

Finish: CU

-

Wire Diameter: 0.045

-

Package Type: Drum

-

Package Size: 500

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 31.25

-

Pkgs per Pallet: 4

-

Pallet LBS: 2000

-

AWS: ER80S-D2, ER90S-D2