The NS National-Arc™ Copper-Glide™ NS 101 0.045” Copper-Coated Welding Wire in a 60lb Spool is optimized for performance, making it suitable for welding steel with mill scale, rust, or oil, as well as for single and multi-pass weldments.

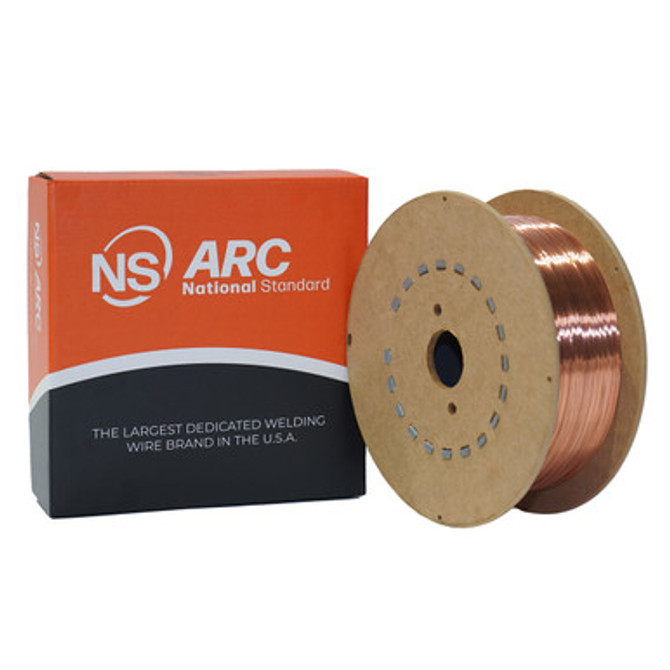

NS National-Arc™ Copper-Glide™ NS 101 0.045” Copper-Coated Welding Wire 60lb Spool

The NS National-Arc™ Copper-Glide™ NS 101 0.045” Copper-Coated Welding Wire in a 60lb Spool is a solid premium filler metal that promotes unbeatable weld performance and strength. It’s a reliable choice for dealing with heavy-duty welding jobs that require improved feedability and enhanced weldability. This wire provides a precise and controlled welding experience that is especially beneficial for intricate projects.

Applications for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 101 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 101 welding wire goes beyond the ordinary, offering a host of unique benefits that enhance the weld performance. This welding wire boasts superior arc starts, arc stability, and feedability, as well as minimal spatter and superior copper adhesion. It’s the best choice for applications requiring a minimum 70,000 psi tensile strength.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

For optimal performance, Copper-Glide™ NS 101 requires specific shielding gas blends such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

It is also compatible with all-position welding, provided that the correct shielding gas blends, welding process, and welding parameters are used.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 101 meets or exceeds various industry standards such as:

- AWS A5.18/A5.18M: ER70S-3

- AWS A5.17: EM13K

- ASME SFA-A5.18: ER70S-3

- CWB W48: B-G 49A 2 C1 S3

- ABS Certified Product - Learn More

Copper-Coated Welding Wire Storage Instructions

Welding wire should be stored in a dry, enclosed environment and in its originally sealed package. This ensures that the welding wire maintains its quality and performance over time.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 101

-

Finish: CU

-

Wire Diameter: 0.045

-

Package Type: Spool

-

Package Size: 60

-

Application: MIG

-

Product Length (inches): 13.88

-

Product Width (inches): 13.88

-

Product Height (inches): 4

-

Pkgs per Pallet: 54

-

Pallet LBS: 3240

-

AWS: ER70S-3, EM13K