The NS National-Arc™ Copper-Glide™ NS 101 0.040” Copper-Coated Welding Wire in a 1000lb Tru-Trac Wood Reel offers superior arc starts, stability, and feedability, minimizing spatter and ensuring a smooth welding process for welders of all levels.

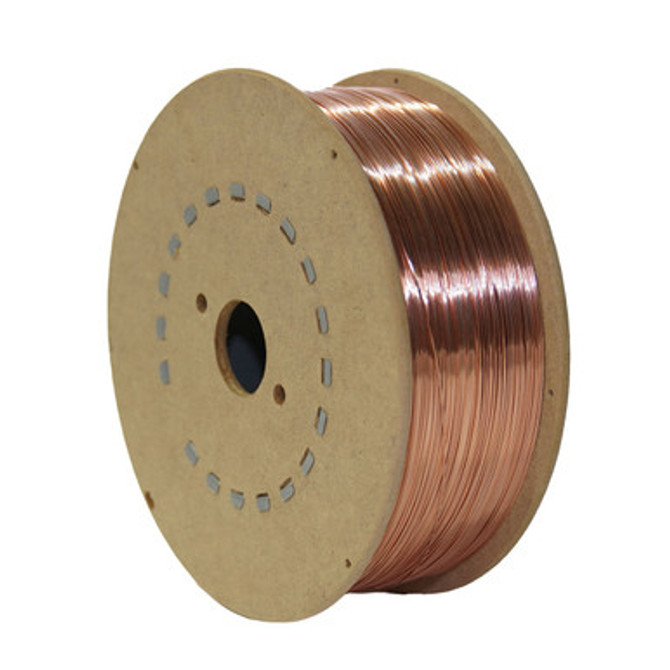

NS National-Arc™ Copper-Glide™ NS 101 0.040” Copper-Coated Welding Wire 1000lb Tru-Trac Wood Reel

The NS National-Arc™ Copper-Glide™ NS 101 0.040” Copper-Coated Welding Wire in a 1000lb Tru-Trac Wood Reel facilitates efficient heat dissipation during welding. This ensures that heat generated during the process is effectively transferred away from the welding wire, preventing overheating and maintaining consistent welding parameters.

Applications for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 101 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 101 welding wire provides our welders with unbeatable versatility, making them suitable for a wide range of applications, including automotive manufacturing and structural steel fabrication. This allows our welders to use the same type of wire for different welding tasks and materials, delivering the same high-quality strength to multiple projects.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

For optimal performance, Copper-Glide™ NS 101 requires specific shielding gas blends such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

It is also compatible with all-position welding, provided that the correct shielding gas blends, welding process, and welding parameters are used.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 101 meets or exceeds various industry standards such as:

- AWS A5.18/A5.18M: ER70S-3

- AWS A5.17: EM13K

- ASME SFA-A5.18: ER70S-3

- CWB W48: B-G 49A 2 C1 S3

- ABS Certified Product - Learn More

Copper-Coated Welding Wire Storage Instructions

Welding wire should be stored in a dry, enclosed environment and in its originally sealed package. This ensures that the welding wire maintains its quality and performance over time.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 101

-

Finish: CU

-

Wire Diameter: 0.040

-

Package Type: Tru-Trac Wood Reel

-

Package Size: 1000

-

Application: MIG

-

Product Length (inches): 30

-

Product Width (inches): 30

-

Product Height (inches): 21.5

-

Pkgs per Pallet: 2

-

Pallet LBS: 2000

-

AWS: ER70S-3, EM13K