The NS National-Arc™ Copper-Glide™ NS 101 0.035” Copper-Coated Welding Wire in a 33lb Spool is an ideal copper-coated welding wire for pipe welding, structural welding, and welding components, offering versatile solutions for various applications.

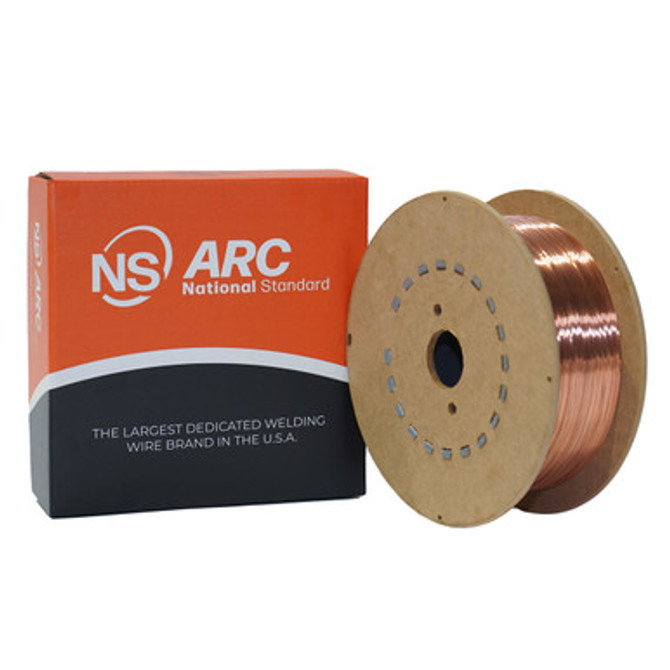

NS National-Arc™ Copper-Glide™ NS 101 0.035” Copper-Coated Welding Wire 33lb Spool

The NS National-Arc™ Copper-Glide™ NS 101 0.035” Copper-Coated Welding Wire in a 33lb Spool is a premium filler metal that promotes greater arc stability and smoother feedability, creating a more productive welding operation. The copper coating enhances the electrical conductivity of the welding wire, ensuring a consistent and efficient flow of electrical current during the welding process.

Applications for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

Our NS National-Arc™ Copper-Glide™ NS 101 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

The NS National-Arc™ Copper-Glide™ NS 101 welding wire is designed to dissipate heat generated during welding more effectively. This is crucial for preventing overheating of the welding wire and maintaining consistent welding parameters, resulting in stronger welds that support the integrity of the rest of the welding project.

Shielding Gas Blends for NS National-Arc™ Copper-Glide™ NS 101 Welding Wire

For optimal performance, Copper-Glide™ NS 101 requires specific shielding gas blends such as:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

It is also compatible with all-position welding, provided that the correct shielding gas blends, welding process, and welding parameters are used.

Copper-Coated Welding Wire Industry Standards

NS National-Arc™ Copper-Glide™ NS 101 meets or exceeds various industry standards such as:

- AWS A5.18/A5.18M: ER70S-3

- AWS A5.17: EM13K

- ASME SFA-A5.18: ER70S-3

- CWB W48: B-G 49A 2 C1 S3

- ABS Certified Product - Learn More

Copper-Coated Welding Wire Storage Instructions

Welding wire should be stored in a dry, enclosed environment and in its originally sealed package. This ensures that the welding wire maintains its quality and performance over time.

Technical Specs

-

Tier: National-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: 101

-

Finish: CU

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 33

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 2376

-

AWS: ER70S-3, EM13K