The Copper-Glide™ Standard-Arc® S-3 0.035” Copper-Coated Welding Wire in a 500lb Drum delivers a smooth and uniform welding arc with minimal weld spatter for the benefit of our welders.

Copper-Glide™ Standard-Arc® S-3 0.035” Copper-Coated Welding Wire 500lb Drum

The Copper-Glide™ Standard-Arc® S-3 0.035” Copper-Coated Welding Wire in a 500lb Drum delivers superior weld performance directly to your projects. Engineered by our experts with meticulous attention to detail, this welding wire ensures maximum weld quality and user appeal for nearly any kind of application that requires our level of welding strength.

Applications for Copper-Glide™ Standard-Arc® S-3 Welding Wire

Our Copper-Glide™ Standard-Arc® S-3 welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

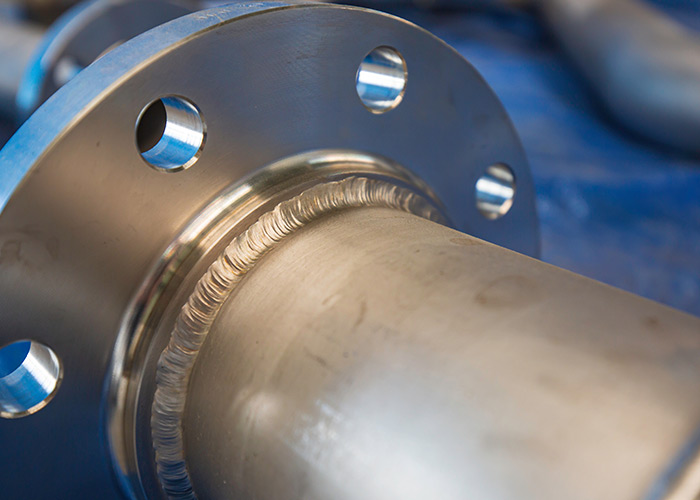

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the NS ARC Copper-Glide™ Standard-Arc® S-3 Welding Wire

The Copper-Glide™ Standard-Arc® S-3 welding wire features a precise balance of manganese and silicon guarantees exceptional deoxidation, which results in the more desirable flat bead profiles and low-spatter welds. It delivers excellent feedability and accurate wire positioning.

Shielding Gas Blends for Copper-Glide™ Standard-Arc® S-3 Welding Wire

Optimal results can be acquired when using the following shielding gas blends with Copper-Glide™ Standard-Arc® S-3 copper-coated welding wire:

- 100% CO2

- 75-95% Argon/Balance CO2

- 95-98% Argon/Balance O2

- Flow rate of 35-50 CFH

Designed with an emphasis on versatility and adaptability, this welding wire allows for all-position welding when using the correct shielding gas blends, welding process, and welding parameters.

Copper-Coated Welding Wire Industry Standards

Copper-Glide™ Standard-Arc® S-3 meets or exceeds various industry standards such as:

- AWS A5.18: ER70S-3, AWS A5.18M: ER48S-3

- ASME SFA-5.18: ER70S-3

- CWB W48: B-G 49A 2 C1 S3

Copper-Coated Welding Wire Storage Instructions

Proper storage is crucial to maintaining the quality and performance of your welding wire. Make sure that you properly store the Copper-Glide™ Standard-Arc® S-3 in a dry, enclosed environment and ensure it remains in its original sealed package. By following these storage guidelines, you can preserve the integrity of your welding wire for future use.

Download Carbon Steel Welding Wire SDS

Download Canadian Welding Wire SDS

Download Copper-Coated Welding Wire French SDS

Download Carbon Steel Welding Wire French SDS

Download Standard-Arc® Welding Wire French SDS

Download Copper-Coated Welding Wire Spanish SDS

Technical Specs

-

Tier: Standard-Arc

-

Branding: Copper-Glide

-

Class: Carbon

-

Alloy: StdArc S-3

-

Finish: CU

-

Wire Diameter: 0.035

-

Package Type: Drum

-

Package Size: 500

-

Application: MIG

-

Product Length (inches): 20.4

-

Product Width (inches): 20.4

-

Product Height (inches): 31.25

-

Pkgs per Pallet: 4

-

Pallet LBS: 2000

-

AWS: ER70S-3, EM13K