Boasting corrosion resistance and high electrical conductivity, Alumi Glide® 0.188” 5356 Aluminum TIG Welding Wire in a 10lb carton is compatible with various aluminum alloys. It offers versatility for welding projects across different grades and thicknesses.

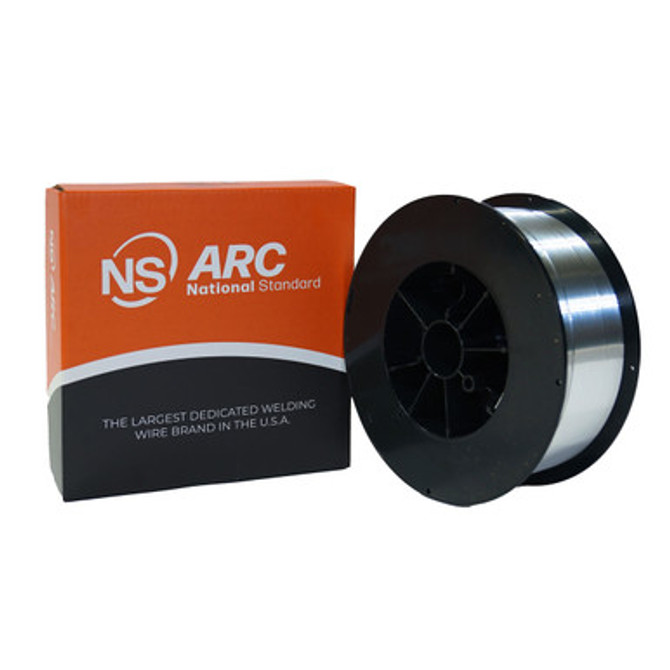

Alumi Glide® 0.188” 5356 Aluminum TIG Welding Wire 10lb Carton

Beyond its lightweight and versatile nature, Alumi Glide® 0.188” 5356 Aluminum TIG Welding Wire in a 10lb carton offers distinctive advantages, including low fume emission, corrosion resistance, high electrical conductivity, and compatibility with various aluminum alloys, including 5050, 5052, 5083, 5356, 5454, and 5456 metals. Its unique control ensures consistent feeding for manual or robotic applications.

Applications for Alumi Glide® Welding Wire

Alumi Glide® aluminum welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of Alumi Glide® Welding Wire

The Alumi Glide® 5356 aluminum welding wire features a melting range of 1060-1175°F, a density of 0.96 lbs./ci., and a typical tensile strength of 38,000 psi. With a superior wire surface finish, it offers trouble-free welding for easier handling. Suitable for a wide variety of welding applications, including pipe welding and structural welding, our aluminum welding wire provides unmatched performance.

Shielding Gas Blends for Alumi Glide® 5356 Welding Wire

When using the following shielding gas blends, optimal results can be acquired with Alumi Glide® 5356 aluminum welding wire:

- 100% Argon

- Argon/Helium Mixtures

This versatile TIG/MIG welding wire can be used in all positions. Factors such as appropriate shielding gas usage, settings, and arc transfer modes are required for welding.

Aluminum Welding Wire Industry Standards

Alumi Glide® meets or exceeds several industry specifications, including:

- AWS A5.10 classification ER5356, R5356

- CWB A5.10

- ISO 9001:2015

- ABS Certified Product - Learn More

Aluminum Welding Wire Storage Instructions

In order to maintain the integrity and longevity of your welding wire, proper storage is essential. We recommend storing our Alumi Glide® 5356 in a dry, enclosed environment and keeping it sealed in its original package.

Technical Specs

-

Tier: National-Arc

-

Branding: Alumi Glide

-

Class: Aluminum

-

Alloy: 5356

-

Finish: ALM

-

Wire Diameter: 0.188 (3/16)

-

Package Type: Carton

-

Package Size: 10

-

Application: TIG

-

Product Length (inches): 0

-

Product Width (inches): 0

-

Product Height (inches): 0

-

Pkgs per Pallet: 0

-

Pallet LBS: 0

-

AWS: ER5356, R5356