The Alumi Glide® 0.188” 4043 Aluminum TIG Welding Wire in a 10lb carton features superior wetting characteristics and offers reduced crack sensitivity. It’s recommended for base metals 3003, 3004,5052, 6061, 6063, and casting alloys 43, 355, 356, and 214.

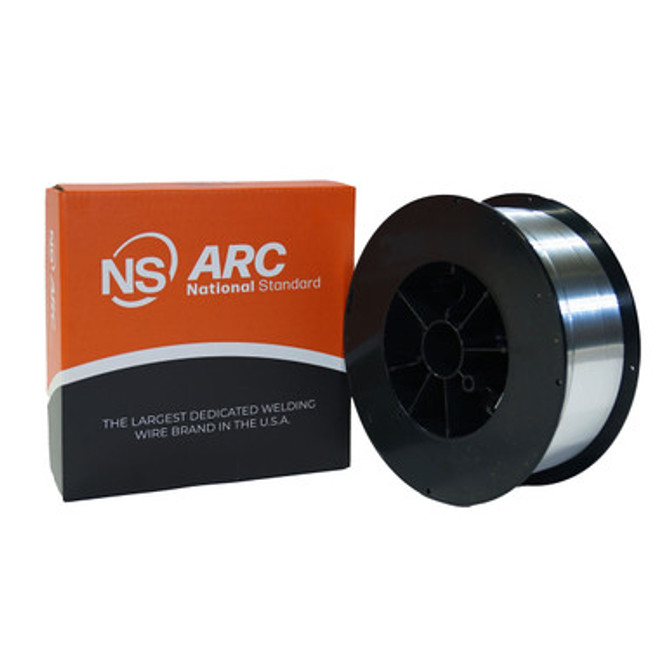

Alumi Glide® 0.188” 4043 Aluminum TIG Welding Wire 10lb Carton

The Alumi Glide® 0.188” 4043 Aluminum TIG Welding Wire in a 10lb carton offers unbeatable welding performance and high strength-to-weight ratio, providing our welders with the ability to join, repair, fabricate, customize and modify aluminum components with ease. Suitable for both robotic and manual welding operations, our high-quality aluminum filler metal offers great wetting characteristics for smoother welding.

Applications for Alumi Glide® Welding Wire

Alumi Glide® aluminum welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of Alumi Glide® Welding Wire

The Alumi Glide® 4043 aluminum welding wire, which contains 5% silicon composition, can help achieve superior bonds with its lightweight and high strength-to-weight ratio. It can work with non-heat treatable weldments and with welding 6XXX series alloys and most aluminum cast alloys (mold repair).

Shielding Gas Blends for Alumi Glide® 4043 Welding Wire

When using the following shielding gas blends, optimal results can be acquired with Alumi Glide® 4043 aluminum welding wire:

- 100% Argon

- Argon/Helium Mixtures

This welding wire can be used in all positions. Appropriate shielding gas usage, settings, and arc transfer modes are required for welding.

Aluminum Welding Wire Industry Standards

Alumi Glide® meets or exceeds several industry specifications, including:

- AWS A5.10 classification ER4043, R4043

- Canadian Bureau of Welding – CWB A5.10

- ISO 9001:2015

Aluminum Welding Wire Storage Instructions

It is recommended to store Alumi Glide® 4043 in a dry, enclosed environment and in its originally sealed package to prevent contamination.

Technical Specs

-

Tier: National-Arc

-

Branding: Alumi Glide

-

Class: Aluminum

-

Alloy: 4043

-

Finish: ALM

-

Wire Diameter: 0.188 (3/16)

-

Package Type: Carton

-

Package Size: 10

-

Application: TIG

-

Product Length (inches): 0

-

Product Width (inches): 0

-

Product Height (inches): 0

-

Pkgs per Pallet: 0

-

Pallet LBS: 0

-

AWS: ER4043, R4043