The Satin Glide™ 308L 0.035” Stainless-Steel Welding Wire in a 45lb spool can help our welders achieve strong and durable welds with ease and efficiency. Its numerous benefits create welds that meet stringent requirements.

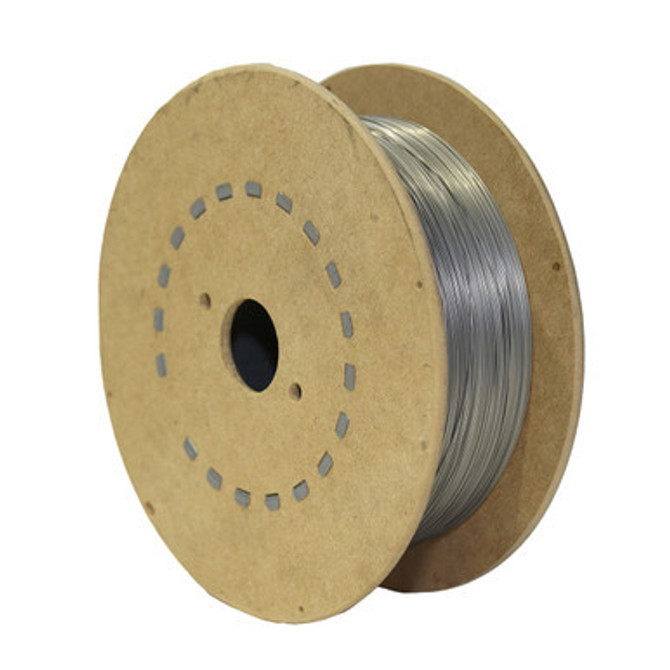

Satin Glide™ 308L 0.035” Stainless-Steel Welding Wire 45lb Spool

The Satin Glide™ 308L 0.035” Stainless-Steel Welding Wire in a 45lb spool is a strong and reliable austenitic filler metal that creates strong and reliable welds. The low carbon content in our welding wire minimizes the risk of carbide precipitation and intergranular corrosion. This feature ensures the integrity of the welded joint, contributing to the longevity and reliability of the fabricated structures.

Applications for Satin Glide™ Welding Wire

Satin Glide™ welding wire is best suited for the following applications:

- Agricultural Equipment

- Auto Body

- Automotive Exhaust

- General Fabrication

- Heavy Equipment

- Pipe Welding

- Pressure Vessels

- Railcars

- Shipbuilding

- Structures

- Trailers

Advantages of the Satin Glide™ Welding Wire

The Satin Glide™ 308L welding wire works well on 301, 302, 304, 304L, 305, 308, and 308L types of stainless steels. Along with the lower carbon content, the higher silicon content improves the wetting of the base material to potentially increase the weld’s travel speed, which can result in higher productivity.

Shielding Gas Blends for Satin Glide® Welding Wire

When it comes to shielding gas blends, Satin Glide® can be used with a variety of options, such as:

- Short Circuit Transfer: 90% Helium, 7-1/2% Argon, 2-1/2% CO2

- Spray Transfer: 95-98% Argon, 2-5% CO2

- Spray Transfer: 98-99% Argon, 1-2% O2

- Flow rate: 35-50 CFH

All-position welding is possible with Satin Glide® as long as the correct shielding gas blends, welding process, and welding parameters are used.

Stainless-Steel Welding Wire Industry Standards

Satin Glide® meets or exceeds several specifications, including:

- AWS A5.9/A5.9M: ER308, ER308L

- ASME SFA-A5.9: ER308, ER308L

- ASME Section III Nuclear requirements

Stainless-Steel Welding Wire Storage Instructions

For storing the welding wire, make sure that it is kept in a dry location in a clean and organized manner to prevent any contact with dirt, dust, or debris, which can affect the wire’s overall quality and performance.

Technical Specs

-

Tier: National-Arc™

-

Branding: Satin Glide®

-

Class: Stainless

-

Alloy: 308L

-

Finish: STN

-

Wire Diameter: 0.035

-

Package Type: Spool

-

Package Size: 45

-

Application: MIG

-

Product Length (inches): 11.75

-

Product Width (inches): 11.75

-

Product Height (inches): 4

-

Pkgs per Pallet: 72

-

Pallet LBS: 3240

-

AWS: ER308L